- Services

SOFTWARE & AUTOMATION

Next Level Robotics provides comprehensive software and automation solutions, ensuring seamless integration of robotic systems, industrial automation, and intelligent control mechanisms.

SOFTWARE

DEVELOPMENT

BACKEND DEVELOPMENT

Backend development forms the foundation of industrial software solutions, handling data processing, communication protocols, and system logic.

- Real-time Data Processing: Utilizing technologies like C++, Python, and C# for efficient data handling and processing.

- Database Management: Implementing SQL and NoSQL databases to store and manage machine and process data securely.

- Cloud & Edge Computing: Enabling remote monitoring and control through cloud-based or edge computing solutions.

- API & Middleware Development: Creating custom APIs for seamless integration between machines, control units, and enterprise resource planning (ERP) systems.

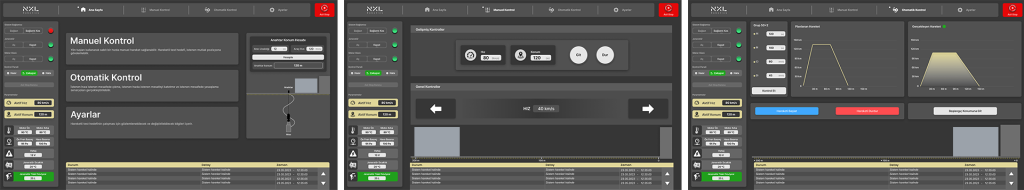

FRONTEND DEVELOPMENT WITH UI&UX DESIGN

User interaction is critical in industrial environments, and Next Level Robotics designs intuitive and responsive graphical user interfaces (GUI) for:

- HMI (Human-Machine Interface): Developing interactive dashboards with real-time data visualization for better system control.

- SCADA (Supervisory Control and Data Acquisition) Interfaces: Enabling comprehensive system monitoring and control with web-based or local SCADA panels.

- Custom Control Panels: Tailoring web-based or desktop control applications for industrial machines and robotic systems.

EMBEDDED SOFTWARE

1. Microcontroller & FPGA Development

Embedded software is critical for real-time control of robots and automation systems. Next Level Robotics specializes in:

- Firmware Development: Writing low-level C/C++ and Rust code for microcontrollers like STM32, TI, and PIC.

- RTOS (Real-Time Operating Systems): Implementing FreeRTOS, VxWorks, or Zephyr for deterministic execution of robotic tasks.

- FPGA-based Processing: Utilizing VHDL/Verilog for ultra-fast signal processing in motion control applications.

2. Communication Protocols

To ensure seamless machine-to-machine communication, embedded systems support:

- Industrial Protocols: Modbus, CANopen, EtherCAT, PROFIBUS, OPC UA.

- Wireless Communication: IoT-based Wi-Fi, Bluetooth, Zigbee, LoRa, 5G for remote monitoring.

- Custom Bus Architectures: Developing high-speed SPI, I2C, and UART communication for sensor integration.

AUTOMATION

SYSTEMS

CONTROL SYSTEMS

Next Level Robotics provides advanced control architectures that govern robotic movements and industrial automation.

PLC (Programmable Logic Controller) Systems

- Developing custom ladder logic and structured text programs for real-time industrial control.

- Supporting major PLC brands like Siemens (TIA Portal), Beckhoff (TwinCAT), Allen-Bradley (RSLogix),Omron and Mitsubishi.

PC-based Control

- Implementing real-time control algorithms on industrial PCs for complex automation applications.

- Using C++, Python, and C# for soft PLC and control logic.

Motion Control Systems

- Developing custom PID, feedforward, and AI-based motion control for robotic arms and CNC machines.

- Integrating servo drives, stepper motors, and linear actuators with real-time feedback loops.

ROBOTICS & AI BASED AUTOMATION

Next Level Robotics specializes in AI-enhanced automation to optimize manufacturing and process efficiency.

AI & Computer Vision

Implementing deep learning-based object detection for quality control. Developing vision-based pick-and-place systems with OpenCV, TensorFlow, and PyTorch.

Connecting machines with IIoT gateways for real-time analytics and predictive maintenance. Utilizing MQTT, OPC UA, and Edge AI to create intelligent manufacturing ecosystems.

Industrial IoT (IIoT) & Smart Factories

Collaborative & Autonomous Systems

Programming collaborative robots (cobots) for human-machine interaction. Developing autonomous mobile robots (AMRs) for warehouse and logistics automation.